Delving into the artisanal mastery of metal casting requires not only a creative spirit but also an intricate understanding of the necessary tools and techniques, all while upholding the highest safety standards. Whether you are an aspiring metalworker or a seasoned professional looking to refine your craft, this exploration will equip you with the knowledge to transform raw metals into works of art with precision and care. Join us as we navigate through the nuanced art of manual metal casting.

Table of Contents

The Key Tools for Manual Metal Casting

Even as modern industrial methods often incorporate sophisticated machinery and technology, there exists a segment of artisans and craftsmen who persist in the practice of manual metal casting utilizing time-honored tools. These traditional implements are primarily utilized for handling raw materials, generating heat, shaping the molten metal, and ensuring the safety of those involved in the smelting process.

Below is a list of essential tools used in traditional manual metal casting:

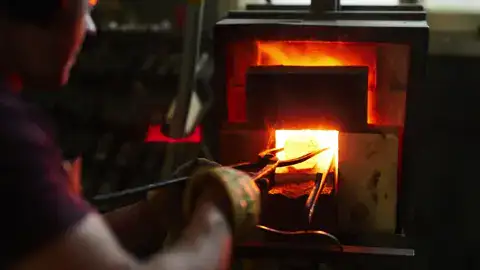

Furnace or Forge: The heart of the smelting process

At the heart of metalworking is the use of a furnace or forge, essential for the transformative process. These crucial structures, in their early forms, were constructed from natural materials like clay or stone, materials strong enough to endure the extreme temperatures needed for melting metals. Despite their simple construction, these early furnaces were far from just basic tools; they were pivotal to the practice of metalworking. They enabled artisans to produce a wide variety of metal items, ranging from practical tools to intricate and ornate works of art.

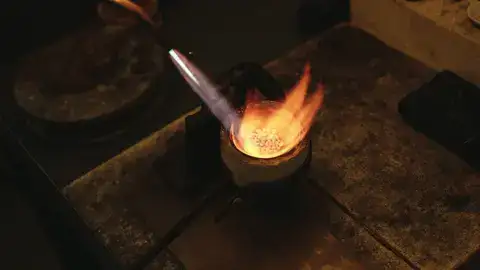

Crucibles: The Heart of Manual Metal Smelting

Crucibles are essential tools in the traditional craft of manually smelting metals, built to withstand the intense heat of furnaces that transform raw ores into workable metals. They are made from durable materials like graphite, which is dense and carbon-rich; silicon carbide, known for its ability to resist high temperatures; and clay composites that have proven effective through time. The type of crucible selected is critical to both the effectiveness and safety of the smelting process. Each crucible is designed for a specific metal and its melting point, as metals require different levels of heat to melt, with some reaching extremely high temperatures.

Using an inappropriate crucible can lead to failure under these harsh conditions, potentially ruining both the craftsman’s work and product. Skilled metalworkers must therefore choose their crucibles wisely, taking into account the specific metal and its melting point, to ensure that the tool can handle the relentless demand of converting ore to metal without compromising on quality or safety.

Molds: Giving Shape to Your Creations

Metalworking is a delicate balance between heat and time, especially when the metal becomes molten and is ready for transformation. At this critical juncture, molds are indispensable for shaping the liquid metal into its new form. Molds must be specifically selected to match the complexity and requirements of each project. For example, cast iron molds are best suited for heavy-duty uses due to their strength, whereas steel molds are preferred for their durability and extended life. For projects needing detailed or bespoke designs, sand molds are ideal because they can be finely shaped to achieve precise patterns.

A critical but sometimes neglected step before pouring the molten metal is preheating the molds. Skipping this step would lead to shocking the metal with a cold mold, causing it to cool too quickly and unevenly shrink. This could introduce stress-related issues such as cracking or unwanted distortions on the surface of the metal, potentially resulting in a piece that is functionally compromised, visually imperfect, or entirely unsuitable for use.

Tongs: Safety and Precision Handling

The critical significance of safety and precision in metalworking is beyond emphasis, especially when dealing with very hot metals. In these high-heat conditions, not only is a worker’s skill important but also the use of particular types of tongs. These tongs are not ordinary tools; they are carefully made from high-quality steel that is especially resistant to heat. This ensures they are durable and dependable, even in extreme environments. Tongs come in various sizes and shapes to suit different casting tasks effectively. Importantly, the best tongs have insulated handles which protect the user’s hands from intense heat, minimizing injury risk and improving the stability of the grip.

Bellows or Blowers: Mastering the Flame

Throughout history, the ability to control fire has marked the advancement of metalworking societies. Fundamental to this expertise is managing heat during metal smelting, which critically involves regulating oxygen flow. In the past, the essential task of controlling airflow was accomplished using bellows made from wood and leather. These traditional tools propelled air into furnaces to feed the fire and melt valuable metals. However, as technology has advanced, modern compact blowers have replaced these bellows. Today’s blacksmiths and metallurgists use these new devices to precisely control airflow, a key component in maintaining the right furnace temperature for metalwork.

Fire-Resistant Gear: Ensuring Your Safety

For those working in high-risk professions such as manual metal casting, where extreme heat and open flames are commonplace, it is critical to wear fire-resistant gear. Protective equipment plays a vital role in safeguarding these workers from the dangers of their job. The intense heat from furnaces can lead to severe workplace accidents, including burns from sparks and molten metal. That is why having a full set of personal protective equipment (PPE) is essential.

This includes specially designed high-temperature gloves that offer both protection and flexibility, ensuring workers can handle tasks safely without losing manual dexterity. Face shields are also an integral part of this safety gear, providing solid protection for the face against both physical particles and intense heat, thereby preventing burns and eye injuries. Lastly, no protective outfit is complete without a flame-retardant apron to protect the body from hot splashes and safety glasses designed to keep the eyes safe from flying fragments.

Conclusion

The craft of manual metal casting is a unique blend of artistic creativity and scientific process, enabling you to produce customized metallic creations with your own distinctive mark. The fundamental tools required include crucibles for melting metals, molds to give shape, tongs for safe handling, bellows or blowers to manage the heat, anvils and hammers to form the metal, and appropriate safety gear to protect yourself. These tools ensure you can safely explore the age-old art of metallurgy.

Approach this craft with the same patience needed to learn a musical instrument or any skillful trade. Arm yourself with these essential instruments, light up your furnace with fervor and exactitude, and watch as you turn bare metal into personally crafted artifacts.