For both metalworking professionals and enthusiasts, understanding the various types of manual shears is crucial for enhancing the quality and efficiency of your projects. These hand-operated tools are indispensable for making accurate cuts without the reliance on large machines. In this discussion, we will delve into the assortment of manual shears that are indispensable to anyone intending to manually cut metal.

Table of Contents

Understanding Manual Shears

Manual shears are a fundamental tool in metal fabrication due to their simplicity and reliability, making them ideal for precise cuts. These hand-operated tools don’t require electricity, an advantage in situations without power. There are different types for various needs: tin snips for detailed cuts, throatless shears allowing cuts of any length in any direction, and bench shears for handling bigger, tougher materials with more leverage.

All types of manual shears are known for delivering clean cuts and are particularly useful for their independence from power sources, making them perfect for working in remote areas or when needing a portable tool. Manual shears combine ease of use with efficient functionality, ensuring precise and accessible cutting in metalworking.

1. Tin Snips: Achieving Perfect Curves

Tin snips, also known as aviation snips due to their aviation industry origins for cutting aluminum, are essential for detailed metalworking. They are designed to cut through thin metal sheets effortlessly, making them a crucial component of any metalworker’s tool collection. Tin snips are available in three main types: straight-cutting for direct lines, left-cutting for leftward curves and shapes, and right-cutting for rightward angles. This selection enables the creation of complex designs and precise cuts without warping the material.

Furthermore, tin snips can be easily recognized by their handle colors—red, green, or yellow—which indicate the cutting direction. This standardized color-coding system is particularly helpful for quick tool identification in environments where time is of the essence. Beyond making clean straight cuts, tin snips excel at crafting broad curves accurately, which is why they are preferred tools in fields like HVAC installation and metal roofing.

2. Compound Snips: Less Effort, Cleaner Cuts

Compound snips are expertly designed to offer a greater mechanical advantage than standard tin snips. Through an innovative leveraged design, they enable users to cut through thick metal with surprising ease and noticeably less effort. This results in increased productivity and minimized fatigue, especially beneficial during long work sessions. Compound snips excel at making prolonged, straight cuts through metal with little effort.

Although they perform similar functions as regular tin snips, compound snips are distinguished by their superior efficiency and comfort for the user in tasks where precision and clean cuts are critical. Their ability to handle tougher materials with exceptional performance makes them an essential tool for professionals in any trade involving metalwork.

3. Straight Pattern Snips: Precision Metal Cutting

Straight pattern snips are precision tools preferred by experts for accurate and efficient cutting. These snips are designed with extended blades that facilitate smooth, continuous straight cuts. They differ from offset snips by having the handles aligned in a conventional manner, which may necessitate extra space when using them; however, this arrangement enhances control and accuracy. Exceptionally capable of cutting various metals cleanly, straight pattern snips are ideal for handling aluminum, copper sheets, and thicker materials like stainless steel. For detailed metalwork or any project that demands precise straight cuts, these snips are the essential hand tool for professionals who prioritize cut quality.

4. Throatless Shears: Cut Without Limits

Throatless shears are the ideal combination of precision and versatility for craftsmen and metalworkers. Traditional shears are limited by a set throat depth, restricting the maximum size of the metal sheet they can handle. However, throatless shears break through this limitation with a design that allows for complete freedom in maneuvering the metal sheet. Users can pivot, rotate, and slide the material in any direction through the blades. This flexibility is essential for creating intricate cuts that go beyond simple straight lines, including complex geometric or flowing organic shapes with ease.

Throatless shears also make it easier to perform internal cuts and handle larger sheets that exceed the capacity of standard shears. They are invaluable in any toolkit for cutting metal, empowering artisans to expand their creative horizons and produce detailed work with a polished finish and high precision.

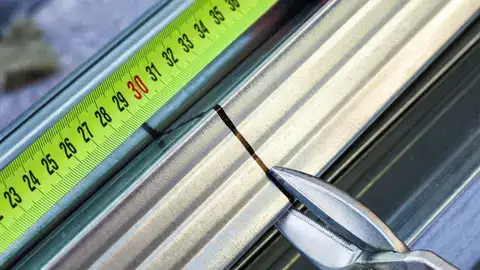

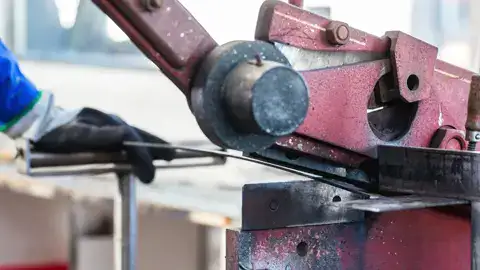

5. Bench Shears: Maximizing Precision and Power

Bench shears are an essential tool in a craftsman’s or metalworker’s toolkit, recognized for their robust build and optimal usability when mounted on a workbench. These shears, which have significantly larger blades than handheld shears, provide enhanced stability and increased cutting strength. They are ideal for cutting through thicker and tougher metals, as their bench-mounted design offers a stable base that allows for precise cuts with minimal effort compared to portable shears.

This feature is especially beneficial for repetitive cutting tasks or working with materials that would be difficult to manage with smaller tools. Bench shears also have long handles which, when combined with the stability of being bench-mounted, lead to an ergonomic design that reduces user fatigue and helps maintain accuracy during prolonged use.

6. Nibblers: The Art of Precision

Hand nibblers, also commonly known as ‘nibblers,’ are essential hand tools praised for their ability to make precise cuts. Unlike standard cutting tools that cut in a smooth continuous fashion—similar to scissors—nibblers create a series of small cuts or “nibbles.” This method allows for exceptional control when cutting sheet metal, making nibblers especially useful for detailed shapes or internal cutouts. They enable the creation of intricate designs and patterns without warping the metal or causing jagged edges. For this reason, craftsmen who demand high precision and gentle handling of materials often favor hand nibblers for their projects.

7. Beverly Shears: The Art of Metal Cutting

Beverly shears are the epitome of fine craftsmanship in the world of heavy-duty cutting tools, designed with precision to effortlessly cut through thick metals. The standout feature of these shears is their unique curved blade design, which is crucial for producing smooth cuts consistently. This innovative blade shape excels at both straight and curved cuts, even around tight radii.

Built ergonomically, the shears offer comfortable use, mitigating fatigue and increasing productivity during extended periods of work. Therefore, for any metalworking task that requires cuts of the highest standards and dependable performance, Beverly shears are a vital tool in both industrial and personal workshop environments.

Finding the Right Tool for Cutting Various Metals

Selecting the right manual shear is a critical and detailed decision that relies on understanding both the material you’re working with and the desired result of your work. It’s important to consider the thickness of the metal, as this determines the necessary strength of the shear you need. Different types of metal, ranging from soft aluminum to tough stainless steel, will affect your selection, as each requires different levels of force and precision during cutting.

Depending on your project’s needs—if you require exact cuts for intricate work or can manage with less precision for basic shapes—this will guide your tool choice. Careful selection is crucial so that the shear not only suits the properties of the metal but also meets the requirements of your project, influencing both how easy the tool is to use and the quality of what you produce. A thoughtful choice can lead to smooth progress in your task, while a hasty one might cause unnecessary problems.

Safety Practices for Manual Shearing Operations

When using manual shears, it’s crucial to wear the right safety gear to protect against possible injuries. Wearing sturdy protective gloves can greatly lower the chances of getting cuts and scrapes from the sharp blades. These gloves help cushion your hands and improve your grip, reducing the risk of accidental slips and related injuries. Additionally, it’s essential to use protective eyewear when cutting. Tiny metal pieces can fly off and hit your face unpredictably. Safety glasses or face shields provide a protective layer to guard your eyes from any airborne debris, ensuring you can see clearly and avoid eye injuries.

Tips on Using Manual Shears

If you’re new to using manual shears or want to improve your technique, consider the following suggestions:

- Keep the blades sharp. Blunt blades not only make cutting more laborious but also pose greater safety risks.

- Hold the shears correctly and use your body effectively to increase leverage and minimize physical strain.

- Before making a cut, ensure the material is firmly secured to prevent movement and to guarantee precise cuts.

- Proceed with care and at a steady pace. Hurrying through the task can lead to errors and potential accidents.

- Regularly clean and lubricate your shears to preserve their cutting efficiency and extend their lifespan.

The Bottom Line

Manual metal shears are prized for their control, adaptability, and precise work in a conveniently portable form. Both artisans who prioritize quality in their craft and individuals needing to cut household sheet metal find them essential. Equipping yourself with a top-notch pair of manual shears not only saves time and effort but also guarantees superior finishes for your projects.

Selecting the right pair of manual shears goes beyond adding to your tool collection. It’s about endorsing the value of handcrafted precision where skilled handwork and intelligent design converge, enabling you to produce exemplary metalwork with each cut.