Embarking on a career path as an electrician offers a rewarding experience, yet it is not without inherent risks. Ensuring job safety goes beyond simple compliance with protocols—it’s fundamentally about the commitment to return home each day unscathed. Given the omnipresent dangers such as electrical shocks and burns, equipping oneself with electrician safety equipment is not a mere option but an indispensable mandate. Hence, it’s imperative for electricians to have access to and utilize appropriate safety gear, reinforcing their defense against potential injuries while they diligently execute their responsibilities.

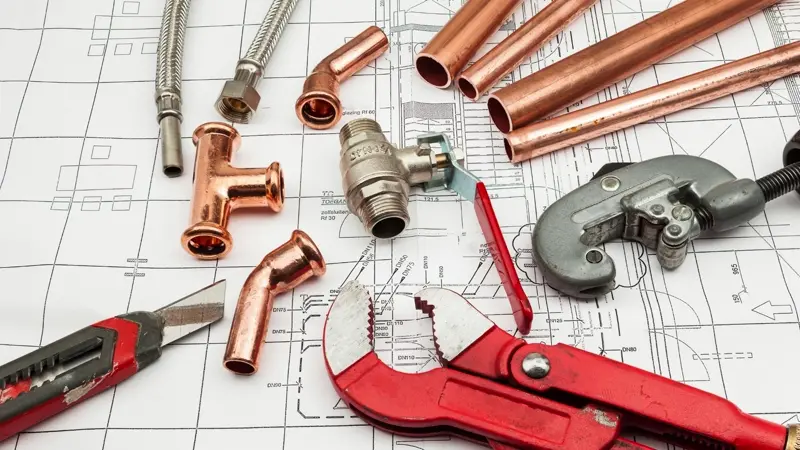

Special electrician’s tool kit

Firstly, insulated hand tools, a fundamental component of electrician safety equipment, are indispensable when working with electricity. These safety-centric tools are critical for safeguarding against electrical shocks and short circuits—common hazards for electricians. Insulated hand tools are constructed to comply with rigorous safety standards and hold specific voltage ratings, ensuring that electricians are abundantly protected, even in the most perilous of conditions.

A robust electrician’s toolkit should comprise essential electrician safety equipment such as insulated screwdrivers, pliers with non-conductive grips, and wire strippers coated with dielectric materials. These tools are all meticulously engineered to avert the conduction of electricity. By incorporating these specialized items into their repertoire of safety equipment, electricians can perform their duties with assuredness, fortified by a dependable line of defense against the hazards posed by the intricate networks of wires and circuits they encounter on a daily basis.

Personal Protective Equipment (PPE) for Electricians

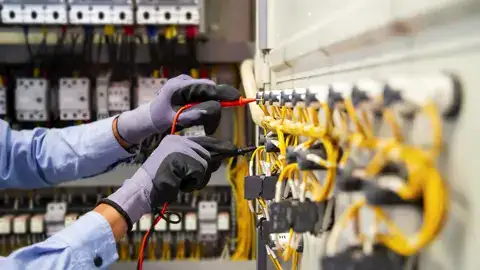

Personal Protective Equipment (PPE) is crucial for electricians to maintain safety and protect themselves from common hazards. This gear includes insulating gloves and sleeves, which are selected based on the electricians’ specific voltage needs, to prevent electrical shocks. Safety glasses with durable side shields are also necessary to protect against flying debris or sparking incidents.

Additionally, hard hats are essential for safeguarding against head injuries that could result from falling objects or navigating in low-clearance spaces. These protective items together form a vital defense for electricians working in dangerous environments.

Proper Footwear and Flame-Resistant Clothing

The importance of wearing the right shoes in the electrical trade is critical for safety, acting as an essential shield against electrical dangers. It’s crucial for electricians to choose shoes or boots that do not conduct electricity, preventing deadly electric currents from passing through the body. Beyond insulation against electricity, these shoes need to provide excellent traction and stability to reduce the risk of slips and falls, common hazards in areas where electricians work.

Alongside durable footwear, it’s also vital for electricians to wear flame-resistant (FR) clothing to protect against thermal hazards like arc flashes. These sudden bursts can release intense heat, light, and energy that may cause severe burns or start fires close by. Flame-resistant clothing is key because it’s hard to set on fire and can self-extinguish quickly, giving electricians extra time to escape dangerous situations and avoid serious injuries or death.

Essential Arc-Flash Protection Kits

Arc-flash protection kits are a critical safety tool for people working near electrical hazards. These kits typically contain face shields and headgear designed to withstand the intense heat of an arc flash—an electrical explosion that can happen during a short circuit or while servicing electrical equipment. Wearing this gear is vital to prevent severe burns and potential fatalities for those working in such dangerous conditions.

Voltage Detectors

Adding voltage detectors enhances safety further by allowing workers to check for active electrical parts before starting their tasks. These handheld tools are crucial because they alert the user to electrical charges in equipment or wires, helping prevent contact with live circuits and reducing the risk of arc flash accidents.

Tags and Locks: Essential Safety Protocols

At the heart of this proactive safety strategy are lockout/tagout devices, essential for managing dangerous energy and promoting a safe environment during maintenance or repair tasks. Lockout devices secure power sources by adding a sturdy lock that holds them in an off position. This precaution ensures that power remains off and cannot accidentally be switched on while someone is working, reducing the likelihood of electrical shocks or other types of energy-related harm. Tagout devices enhance these safety procedures by placing a noticeable tag on the lock.

Effective Communication through Safety Signs and Labels

Safety signs and labels are essential in maintaining electrical safety. They serve as permanent visual cues, offering both warnings in high voltage areas and safe-operating procedures for equipment. By reducing potential misunderstandings, these safety measures increase awareness and help protect everyone present at the workplace.

Conclusion

Electricians face unique risks in each task they undertake, necessitating the implementation of specific safety measures and the use of electrician safety equipment. Wearing personal protective equipment (PPE) from head to toe, such as hard hats and non-conductive shoes, coupled with using specialized tools, is crucial for operation safety. This gear is vital in preventing accidents and injuries. Comprehensive training is the foundation of fostering a safety-first culture—this is a commitment that professional electricians dedicate themselves to daily on every job site.