The mastery of Soldering blends artistic finesse with scientific precision, a duality that becomes critical in the intricate sphere of Soldering electronic devices. Professionals and avid hobbyists alike recognize that selecting the appropriate tools is pivotal in achieving flawless repairs or modifications. This blog post is dedicated to detailing the indispensable soldering instruments for electronics, providing key insights designed to elevate your workmanship in both exactness and efficiency.

Mastering the Fundamentals of Electronic Soldering

Embarking on a journey through the intricacies of Soldering electronic devices necessitates an understanding of soldering—where precise application of a melted filler material, or solder, forms an integral joint between components. The exactitude and cautious approach this task demands can’t be overstated, given the susceptibility of electronic parts to heat and electrostatic disturbances. Presented herein is an Essential Inventory of Soldering Apparatus.

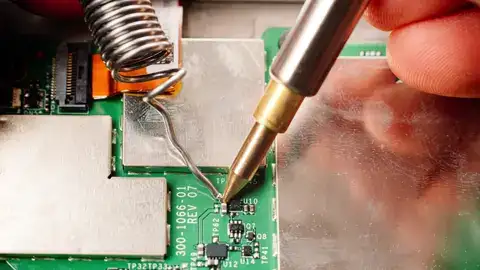

Soldering Iron: A Staple of Electronic Soldering

Soldering irons stand as crucial instruments for electronics assembly and repair, demanding precision and adeptness. They are pivotal for both professionals and enthusiasts in achieving high-quality solder joints. The core purpose of a soldering iron is to accurately heat and melt solder, which is a fusible alloy, to ensure a smooth flow into the joint, creating a secure and reliable electrical connection between components.

The key to masterful soldering involves more than a steady hand; it necessitates the judicious choice of the soldering iron. Premium soldering irons are equipped with adjustable temperature controls to cater to various solder types and component heat tolerances. This adaptability is critical—excessive heat may irreparably damage sensitive electronics, while inadequate heat can lead to weak joints, undermining the integrity of the electrical circuitry and potentially deteriorating device performance.

Solder: The “Glue” in Electronic Soldering

Rosin-core solder, in particular, stands out as an indispensable element for Soldering electronic devices. This variant is infused with a rosin-based flux core, which significantly enhances wettability, allowing for a more uniform spread and thus bolstering the strength of electrical connections. The meticulously crafted composition of rosin-core solder offers superior electrical conductivity, a critical factor for the seamless performance of electronic apparatus. Moreover, its preference within the industry is further justified by its non-corrosive nature post-application, averting potential damage to sensitive circuitry and contributing to the longevity of electronic components.

Flux: Enhancing Solder’s Ability

Flux is essential in soldering, serving as a critical agent for establishing strong, reliable connections. It functions as an efficient cleaner, preparing metal surfaces by removing impurities and preventing oxidation, thereby preserving the metals’ inherent properties. This is vital for maintaining electrical conductivity and structural integrity. Upon the application of heat, flux activates to enhance the solder flow and inhibit oxide formation, resulting in smooth joints. Flux thus ensures not only the visual seamlessness of components but also fortifies the internal connections of electronic devices against long-term wear and stress.

Desoldering Pump: Correcting Mistakes

Electronic device Soldering requires meticulous attention to detail and expertise. However, even skilled technicians may experience soldering faults or subpar joints. For effective error correction without additional harm to components, the desoldering pump is indispensable. Often known as a solder sucker, this tool proficiently removes molten solder from defective connections during repair or disassembly. The user-friendly desoldering pump employs a simple mechanism: it vacuums the liquified solder upon activation, typically via button or trigger, thereby cleaning the intended site and ensuring a spotless work area.

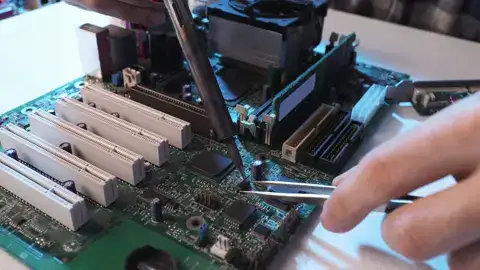

Tweezers and Clamps: The Hands You Need

Precision tweezers are essential for professionals working with intricate components, offering superior control to prevent damage to dense electronic configurations. Parallelly, clamps provide a secure hold, eliminating the risk of movement that could cause suboptimal soldering or damage to sensitive circuitry. Together, these tools are fundamental for maintaining the high standards required in technical operations.

Wire Cutter and Stripper: Preparing Your Components

In the precision-driven field of electronic device Soldering, mastery over wire cutters and strippers is indispensable. These tools are crucial for achieving exacting standards in electrical connections. Wire cutters allow technicians to remove excess leads with precision, while wire strippers gently remove insulation, safeguarding the integrity of the underlying conductive material.

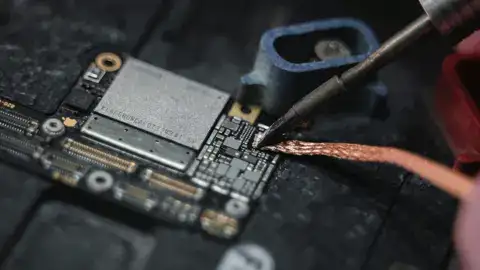

Solder Wick: Removing Excess Solder

In the realm of precision electronics, the solder wick stands as a critical implement for technicians. This copper braid is specifically engineered to absorb excess molten solder, thereby preventing short circuits and enhancing connection reliability. Its utilization is straightforward yet sophisticated: positioned on a surplus-laden solder joint and heated, the wick employs capillary action to remove superfluous solder, purifying the joint. This process not only improves the aesthetic of the solder points but is vital in fortifying their structural fortitude and ensuring optimal electrical functionality in electronic devices.

Heat Gun or Hot Air Rework Station

In the specialized field of electronic Soldering, advanced tools such as heat guns and hot air rework stations are pivotal for enhancing precision and safety. These devices utilize targeted hot air to execute reflow soldering, circumventing the need for physical contact with fragile components. Heat guns produce a focused hot airstream, adjustable to the optimal temperature required for melting solder and securing or desoldering electronic elements from printed circuit boards. They are exceptionally advantageous for tasks involving surface-mounted devices (SMDs), where conventional soldering is impractical or potentially harmful to sensitive parts.

Notably, hot air rework stations offer finely tunable air flow and temperature settings, promoting uniform heat distribution, thus reducing the risk of circuitry damage due to overheating.

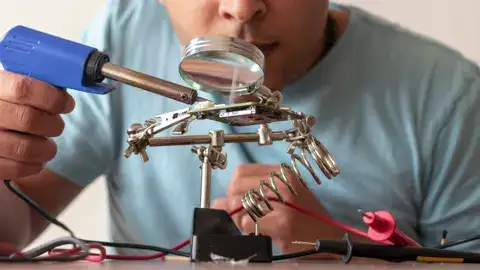

Magnification Equipment: Seeing the Invisible

In the precision-driven realm of electronics, working with minuscule components often invisible to the naked eye is commonplace. Critical to this meticulous work are magnification tools such as loupes and advanced microscopes, which empower technicians and engineers to expand their vision, pinpointing imperfections or essential soldering points on circuit boards. This capability is vital in fortifying the integrity and enhancing the quality of electronic welds, thereby diminishing potential malfunctions in finished devices.

ESD-Safe Equipment: Protect Your Devices from Static

In the precision-driven realm of electronic assembly and repair, proactive measures against electrostatic discharge (ESD) are indispensable. Imperceptible yet ruinous, ESD can compromise the integrity of sensitive electronics. To counteract this invisible threat, employing ESD-safe tools and practices is critical. High-quality anti-static mats create a protective workspace, while grounding wristbands prevent static accumulation on the user, and specialized ESD-proof hand tools ensure secure handling of delicate components. Implementing these measures is a non-negotiable standard to safeguard electronic equipment during all stages of manufacturing and maintenance.

The Bottom Line

Equipping oneself with the finest welding instruments is crucial for the expert execution of repairs and enhancements on electronic devices. High-caliber soldering tools are investments that pay dividends in the precision and functionality of your work, irrespective of your skill level—be it a seasoned professional or an ardent DIY buff. Optimal tools translate directly to superior repair quality, setting the standard for excellence in electronics maintenance.